Gas Repipe and Pressure Testing

Replace Corroded Gas Lines and Confirm Safe Operation With Professional Pressure Testing

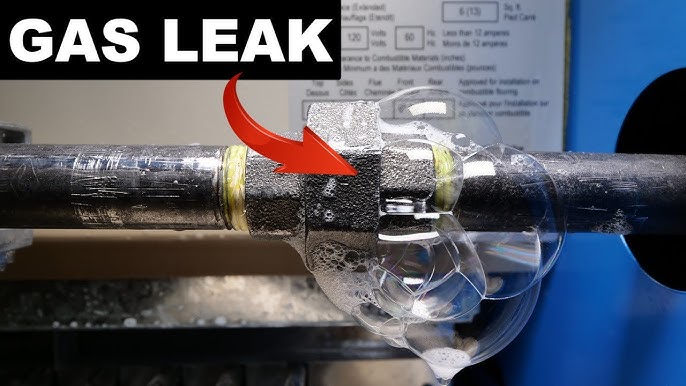

Gas lines corrode over time just like water pipes. Older black iron pipe rusts from the inside when moisture enters the system. Corroded sections develop pinhole leaks that let gas escape into walls and living spaces. New construction and major renovations require complete gas system pressure testing before turning on appliances. The test confirms no leaks exist anywhere in the system under operating pressure. Failed tests mean finding and fixing every leak before gas service gets restored. Licensed plumbers handle gas repiping and testing because mistakes with gas systems cause explosions and deaths.

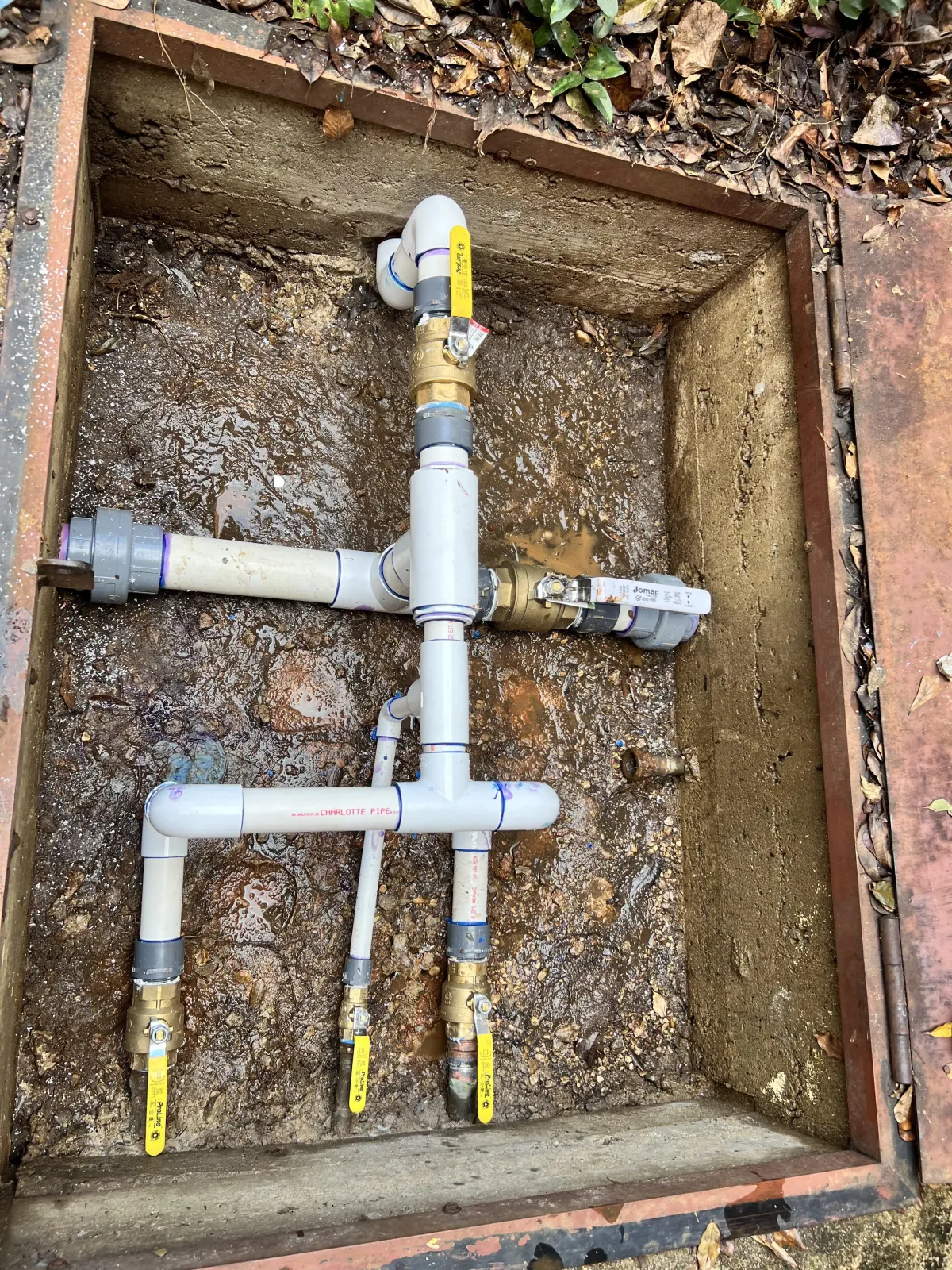

We replace corroded gas lines and install new systems for home additions or converted heating systems. Black iron pipe and corrugated stainless steel tubing both meet code requirements depending on application. Every joint gets tested individually during installation and the entire system undergoes pressure testing before final inspection. Gas pressure gauges measure system integrity over time periods specified by local codes. Soap solutions applied to connections reveal even tiny leaks that pressure gauges miss. Licensed Master Plumber certification means understanding gas pressure requirements, proper pipe sizing for appliance BTU demands, and testing procedures that meet inspector standards.

Never skip gas pressure testing after any work on gas systems. Uninspected repairs and additions risk gas leaks that build up undetected. We serve Jacksonville, Tyler, and East Texas with gas repiping and testing that prioritizes safety. Call (877) 557-9231 for gas line replacement and mandatory pressure testing that keeps your family safe.

What We Offer:

Complete Gas System Repipe – Replace entire gas distribution systems when widespread corrosion or outdated materials compromise safety throughout the home.

Partial Gas Line Replacement – Replace corroded sections while preserving functioning portions to reduce costs when entire system doesn't need replacement.

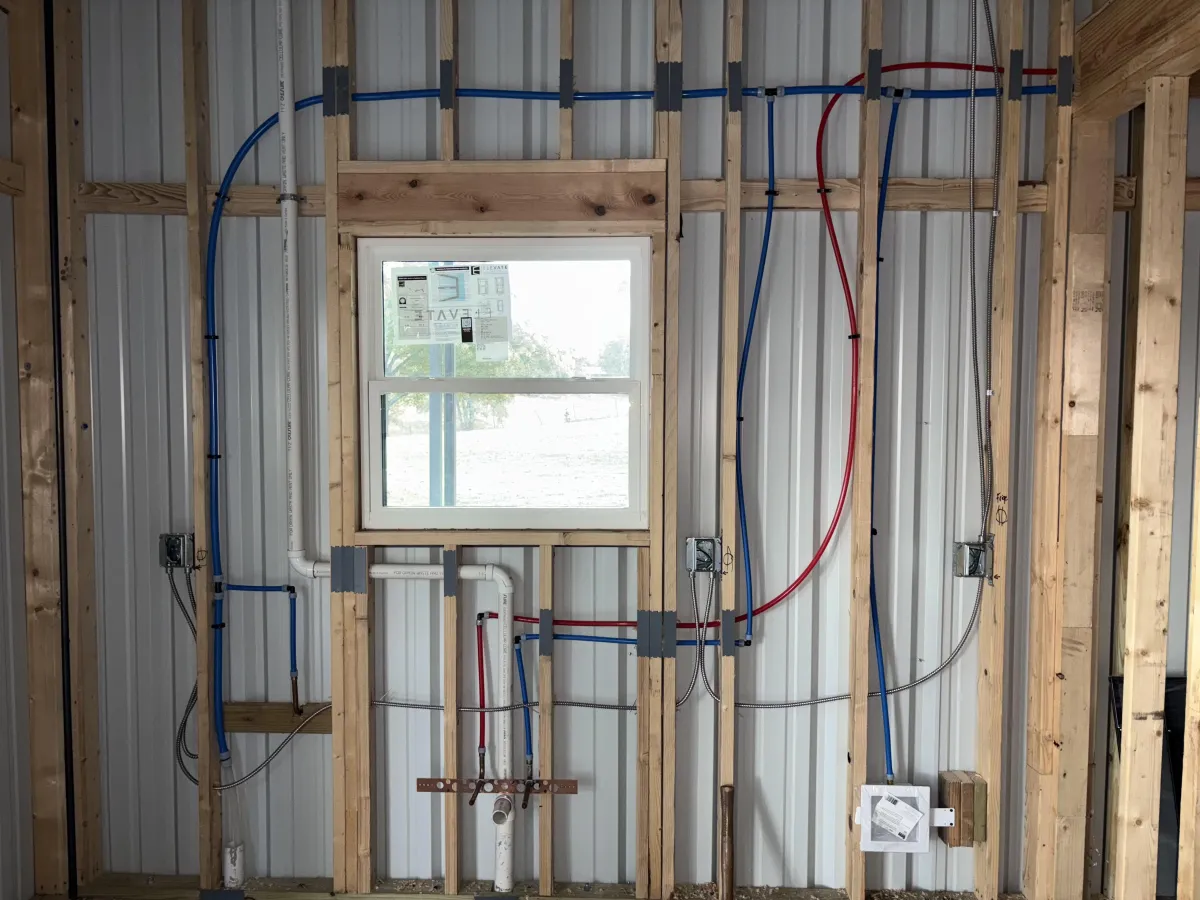

New Construction Gas Installation – Install complete gas systems for new homes including meter connections, distribution lines, and appliance drops.

Addition Gas Line Extensions – Extend existing gas systems to reach new additions, converted spaces, or relocated appliances.

Mandatory Pressure Testing – Test gas systems under operating pressure for specified time periods to confirm no leaks exist before appliance connections.

Leak Detection and Repair – Locate failed pressure test leaks using soap solutions and gauges, repair connections, and retest until system passes.

Code Compliance Documentation – Provide pressure test documentation and inspection coordination required for new construction and major renovations.

Why Choose Texas Plumbing Masters for Gas Repipe and Pressure Testing

Licensed Master Plumber for Gas System Safety – State certification and liability insurance protect homeowners when working with dangerous gas systems requiring expert installation and testing.

Proper Pipe Sizing for Appliance Demands – Calculate correct pipe diameters based on total BTU requirements and run lengths to prevent pressure drops that affect appliance operation.

Thorough Pressure Testing Procedures – Follow code-required testing protocols using calibrated gauges and adequate test durations to confirm system integrity before gas service.

Experience With Local Code Requirements – Familiarity with Jacksonville and Tyler inspection standards means installations and tests pass on first visit without delays.

Eleven Years Installing Gas Systems – Field experience with residential gas distribution means realistic planning for repiping older homes and understanding common failure points.

DISCOVER WHAT OUR CUSTOMERS HAVE TO SAY ABOUT US

REVIEWS

Review us on Google

⭐⭐⭐⭐⭐

Drain backup? No hot water? Leak you can't stop?

Call (877) 557-9231 Now — We Answer Emergency Calls 24/7 and Schedule Fast